Oxygen Generator

Atlasin Company (LLC.) is proud to be the first introducer of the PSA oxygen generation technology to hospitals and the medical community of Iran. For the first time, hospitals as well as patients in need of oxygen had a choice to be self-sufficient, and instead of waiting for trucks carrying heavy oxygen capsules, they were able to produce oxygen safely at the point of consumption at very low pressure.

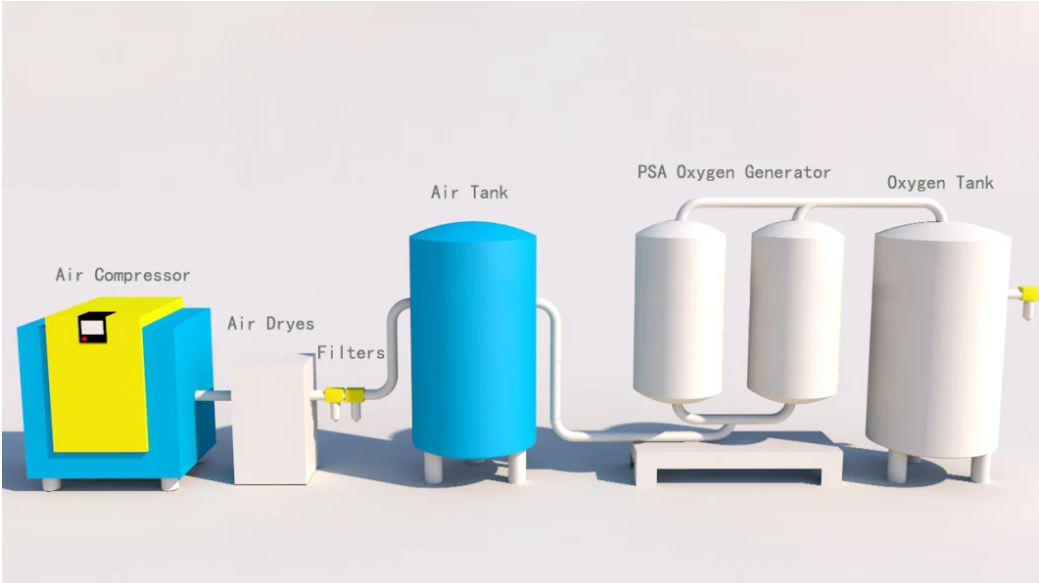

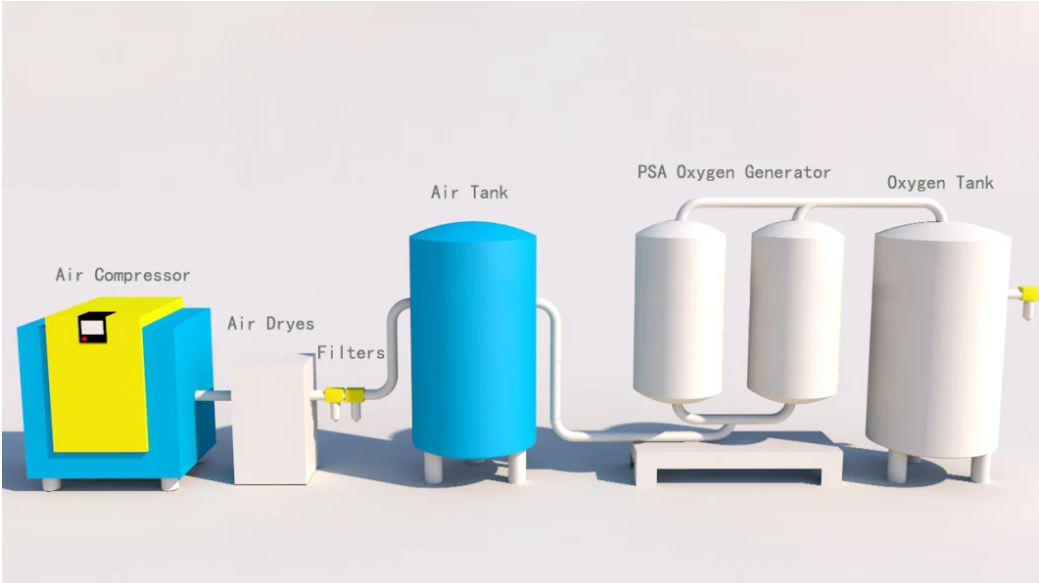

Providing pressurized feed air

The compressor plays a fundamental and indispensable role in Pressure Swing Adsorption (PSA) systems, as the entire gas-separation mechanism relies on supplying air at a stable and sufficiently high pressure. In PSA technology, the selective adsorption of nitrogen by the zeolite occurs efficiently only when the inlet air pressure is within the designed operating range and remains constant; therefore, the compressor functions as the primary driver of the process. The quality, capacity, and stability of the compressor directly influence the oxygen purity, outlet flow rate, efficiency of the adsorption/desorption cycles, and the lifetime of the zeolite beds. Undersized or unstable compressors cause pressure fluctuations that disrupt cycle timing, increase thermal load on the adsorbent, reduce adsorption efficiency, and ultimately lower oxygen concentration. Conversely, a properly selected compressor—with adequate airflow capacity, appropriate power, effective cooling, and proper pre-filtration—ensures that air enters the PSA towers with consistent pressure, temperature, and cleanliness, enabling optimal separation performance. Overall, the compressor serves not only as the mechanical energy source of the PSA system but also as a critical component for operational stability, improved efficiency, reduced energy consumption, and long-term zeolite health.

Crucial Air Treatment

The air dryer is a critical and non-negotiable component in PSA systems because the performance of zeolite adsorbents depends directly on the dryness and quality of the inlet air. Zeolites are highly sensitive to moisture; water molecules rapidly occupy the active adsorption sites, severely reducing the zeolite’s ability to capture nitrogen. This leads to reduced oxygen purity, loss of production capacity, increased bed temperature, shorter adsorbent lifespan, and even permanent zeolite damage. Using a properly selected dryer—whether refrigerated, desiccant, or hybrid—ensures that air enters the PSA towers with a low dew point, minimal humidity, and controlled temperature. This results in stable operation, improved separation efficiency, lower energy consumption, and consistent oxygen purity over time. Therefore, the air dryer is not merely an accessory but a critical protective component in any PSA system.

Twin Tower Oxygen Generation Unit

The oxygen generator unit in a PSA system is the core component responsible for producing oxygen, integrating adsorption towers, pressure-control pathways, cycling valves, and purity-monitoring systems. Using zeolite adsorbents and carefully timed adsorption and regeneration cycles, the generator removes nitrogen from compressed air to deliver an oxygen-enriched stream. Its performance depends heavily on factors such as design integrity, valve timing precision, zeolite quality, stable inlet pressure, and proper thermal management. A properly engineered generator ensures consistent oxygen purity, increased output flow, pressure stability, optimized adsorption cycles, and extended adsorbent life. In contrast, a poorly designed or underspecified generator may lead to purity fluctuations, higher energy consumption, premature zeolite degradation, elevated bed temperatures, and overall system instability. A high-quality PSA oxygen generator must include intelligent control systems, uniform flow distribution, effective moisture management, and real-time purity monitoring to maintain optimal separation efficiency. In summary, the oxygen generator is essential for producing stable, safe, efficient, and high-purity oxygen in PSA installations.

Stabilization of PSA oxygen

The buffer tank is a critical component in PSA oxygen systems, responsible for storing and stabilizing the pressure and flow of the produced oxygen. Because PSA technology operates in cyclic mode—where output flow can fluctuate during each adsorption and desorption cycle—the buffer tank acts as a balancing reservoir that absorbs these variations and ensures a smooth, stable, and uninterrupted oxygen supply to downstream users. By decoupling instantaneous demand from the PSA towers, the buffer tank reduces the dynamic load on valves and adsorbent beds, leading to improved oxygen purity, reduced mechanical stress, minimized pressure fluctuations, and enhanced overall system efficiency. In conditions of peak demand or sudden load changes, the buffer tank prevents pressure drops and allows the PSA unit to maintain its cycles without mechanical strain. Proper sizing and pressure-rating of the buffer tank directly influence purity stability, energy efficiency, and equipment longevity. Therefore, the buffer tank is not merely a storage vessel but a vital stabilizing and protective component for reliable PSA operation.

Molecular Sieves in PSA Gas Separation

Zeolites are crystalline aluminosilicate minerals used as the primary adsorbents in PSA oxygen generators. Their uniform pores and strong framework acidity create selectivity between gases with similar sizes, especially nitrogen and oxygen. When compressed air enters a zeolite bed, nitrogen, moisture, and carbon dioxide are preferentially adsorbed into the pores, while oxygen (which is less strongly adsorbed) passes through as a product gas. The high affinity of zeolites for molecules and their pore structure produce rapid adsorption kinetics, enabling short cycle times and recovery.

During the PSA cycle, the bed alternates between adsorption under high pressure and desorption under reduced pressure, allowing the adsorbed nitrogen to be released and vented. By using two or more beds in a cyclic arrangement, one bed produces oxygen while the other is regenerated. The choice of zeolite (pore size, cation form) tunes purity, flow, and energy use, yielding medical-grade O2 gas of about 90-95%.